Why is a Condition Monitoring Strategy critical for wind turbine efficiency and risk management?

A Condition Monitoring Strategy is vital for ensuring that you have full control over your wind turbines. By continuously monitoring operation and vibration data, you can detect early signs of wear or defects in critical components, preventing failures before they happen. This proactive approach enhances turbine efficiency, reduces unplanned downtime, and minimizes the risk of expensive repairs. It also demonstrates to insurers and stakeholders that your assets are well-managed, reducing risk exposure and improving operational reliability

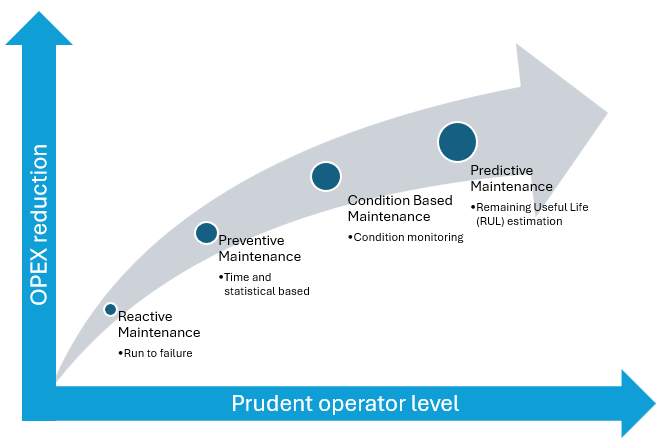

What defines a prudent operator when operating wind turbine drivetrains

A prudent operator implements a condition-based maintenance strategy grounded in data analysis. Regular monitoring of operation and vibration data allows you to detect potential drivetrain issues early, ensuring that turbines operate smoothly. Staying ahead of component failures through predictive maintenance shows that you have strong control over your assets, which not only extends equipment life but also assures stakeholders, including insurers, that you are actively reducing operational risks.

How can data be leveraged to maximize wind turbine availability

Operation and vibration data are critical tools for ensuring maximum wind turbine availability. By analyzing these data streams, operators can detect trends, predict failures, and plan maintenance proactively, rather than reacting to unexpected breakdowns. This data-driven approach allows you to optimize turbine performance, reduce unplanned downtime, and improve overall reliability, ensuring your assets are operating efficiently. With strong data management, operators can maintain a high level of availability and minimize disruptions.

How can an End-of-Warranty (EOW) analysis help minimize financial and operational risks for turbine operators

An End-of-Warranty (EOW) analysis is critical for identifying and resolving potential issues before the warranty expires. Comprehensive analysis of operation and vibration data is essential to target inspections effectively. By analyzing these data sets, you can pinpoint components that are more likely to fail and prioritize them for inspection. This focused approach ensures that necessary repairs or replacements are addressed under warranty, reducing financial risk and maintaining optimal turbine condition to prevent post-warranty failures.

How can Wind Power LAB assist operators in reducing risk and maximizing wind turbine performance?

Wind Power LAB offers specialized support through advanced condition monitoring, Root Cause Analysis (RCA), and predictive maintenance strategies. By partnering with us, you can ensure that your turbines are operating at optimal levels while reducing the risk of unexpected failures. We help you with the documentation package to demonstrate to insurers that you have full control of your assets and are taking the necessary precautions to prevent downtime. Our expertise enables you to make informed, data-driven decisions to maximize turbine performance and minimize operational risks.