Wind Turbine Blade End of Warranty Best Practices

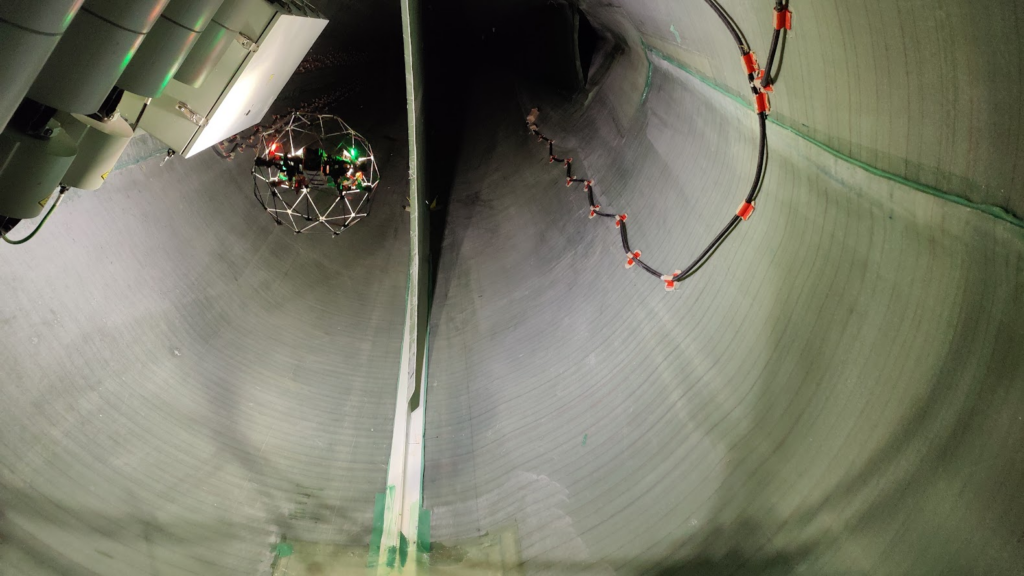

Introduction End of Warranty (EoW) campaigns mark a crucial phase in the operational life cycle of wind turbines. These campaigns involve thorough inspections of major components, rectifying any defects to ensure that the turbine is handed over to the owner without significant damages. In this article, we will delve into the best recommended practices for planning and executing EoW campaigns, with a specific focus on wind turbine blades. Strategic Planning for EoW Campaign The planning for an End of Warranty campaign begins during the development phase, involving agreements on the warranty period after taking over the blades. Manufacturers may offer warranties ranging from 2 to 5 years. Planning is critical, with the inspection campaign ideally scheduled as late as possible within the warranty period. This allows for the development of more defects while still ensuring ample time for inspections and data analysis. Factors to Consider in Planning Lightning-Dense Areas: Schedule inspections during high lightning activity months to test the efficiency of the lightning protection system and address potential issues under warranty. Icing Potential Areas: Plan inspections after the second winter to test the de-icing/anti-icing system under operational conditions. This timing ensures coverage for potential damages caused by ice accumulation. Rain Event Seasonality: Observe as many rain events as possible before EoW inspections to analyze erosion development rates and assess the performance of the leading edge protection. Inspection Scope External Inspections External inspections provide a baseline for surface conditions, leading edge protection performance, erosion development rates, and detection of structural damages in the outer laminate layers. This includes assessing the lightning protection system, potential lightning attachments, and the condition of receptors and add-ons. Internal Inspections Internal inspections are equally important, detecting manufacturing nonconformities such as wrinkles and defects in adhesive bondlines. They also reveal early-life fatigue damages, including major cracks and delamination in inner laminate layers. Analysis and Maintenance Actions Once inspection data is collected, a thorough analysis is conducted to determine the most relevant maintenance actions for each damage. While the common approach is to repair defects during an EoW repair campaign, some defects may warrant a long-term maintenance plan between the owner and the manufacturer. Wind Power LAB can assist in producing claim documents defining the best recommended actions for each defect group, facilitating a smooth transition in the end of warranty claim documentation package. Conclusion End of Warranty campaigns are pivotal for ensuring the longevity and optimal performance of wind turbines. Strategic planning, comprehensive inspections, and informed maintenance actions are key elements in maximizing the benefits of these campaigns. For further insights and detailed discussions on EoW campaigns, reach out to our blade specialists at Wind Power LAB. Don’t be a stranger Feel free to contact us by clicking here