In the world of wind energy, a common challenge faced by wind turbine operators is leading edge erosion. This phenomenon refers to the gradual roughening of the leading-edge surface of the turbine’s blades, which can cause reduced performance and ultimately lead to costly repairs.

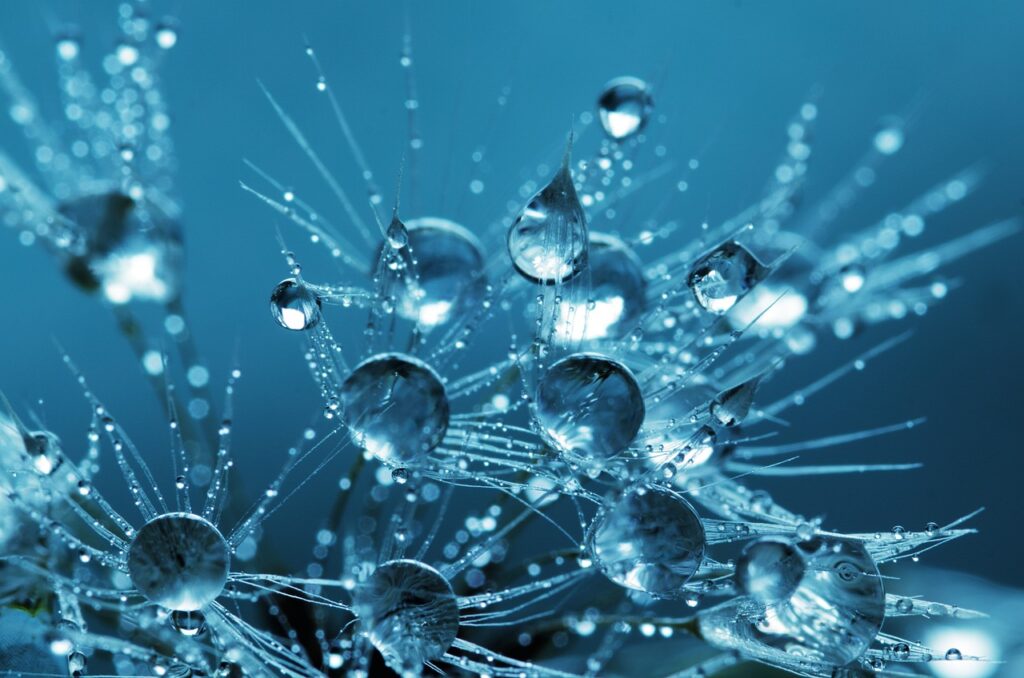

Leading edge erosion is caused by the impact of particles in the air with the surface of the blade. Rain is often the main culprit behind erosion, particularly in areas with high levels of precipitation. However, other atmospheric particles such as dust or hail can also contribute to erosion. Over time, the repeated impacts can cause material to be removed from the leading edge, leaving a rougher surface than before.

Preventing leading edge erosion is crucial for maintaining optimal performance and prolonging the lifespan of wind turbines. Operators may implement measures such as regular inspections, Leading Edge Protection shells. By understanding and addressing this common issue, wind farm operators can help ensure their turbines continue to generate clean energy for years to come.

The power of rain and rotational force.

Wind turbines operate in a variety of weather conditions, and precipitation is a factor that can have a significant impact on their performance and maintenance needs. Due to the rotation of the turbine blades, the blades can encounter more precipitation than what is registered on the ground.

For example, consider a wind farm with an annual accumulated precipitation of 0.7 meters. An average rain droplet falling at a velocity of 6 meters per second will collide with the blade as it moves at 90 meters per second. This results in an accumulated amount of water impacting the leading edge of the blade of 10.5 meters per year.

In contrast, the speed of the droplet hitting the ground is typically much slower, at around 22 kilometers per hour (or 16.67 miles per hour). However, the blade hits the water droplets with much greater force, reaching speeds of up to 324 kilometers per hour (or 201.32 miles per hour) when the turbine is operating at rated speed (Source)

This discrepancy in speed can explain why some areas experience more leading edge erosion than others. Wind farm operators must account for this phenomenon when designing and maintaining their turbines to ensure optimal performance and minimize maintenance costs. By understanding the impact of precipitation on wind turbines, we can continue to improve their efficiency and sustainability in the years to come.

Why is erosion problematic?

Wind turbine blades are carefully designed with an optimized aerodynamic profile to maximize their ability to harvest wind energy. However, leading edge erosion can gradually degrade the blade, reducing its efficiency and ultimately lowering energy production.

To compensate for the erosion, wind turbines may pitch the blades to maintain performance. However, if erosion is not addressed in a timely manner, it can directly impact annual energy production and result in costly repairs. This is particularly true if erosion begins to affect the structural integrity of the blade.

Preventing leading edge erosion is therefore crucial for ensuring the long-term performance and sustainability of wind turbines. Regular maintenance checks can help identify erosion early on, allowing for timely repairs and mitigating the impact on energy production. Operators may also consider implementing erosion-resistant blade designs or protective coatings to help prevent erosion from occurring in the first place.

By taking a proactive approach to leading edge erosion, wind farm operators can help ensure that their turbines continue to generate clean energy efficiently and cost-effectively for years to come.

Some areas are more prone to cause erosion problems than others.

Even wind turbines of the same type can exhibit different levels of leading edge erosion depending on the region where they are located. Wind farms are built in a variety of locations, including onshore and offshore areas with varying levels of precipitation. Some turbines may also have leading edge protection, while others do not.

Research has shown that wind farms located in regions with frequent high rain rates and high wind speeds are more susceptible to leading edge erosion than those in areas with lower precipitation and wind speeds. This can have a significant impact on turbine performance and maintenance costs.

To address this issue, our company collaborated with the Technical University of Denmark on a project called Blade Defect Forecasting. By combining meteorological data from the Danish Meteorological Institute, the expertise of DTU, and our own defect data, we created a machine learning model that can predict which areas are at higher risk of developing erosion.

By leveraging this predictive model, wind farm operators can proactively identify potential erosion hotspots and take preventive measures to protect their turbines. This can help to reduce maintenance costs and increase the long-term sustainability of wind energy.

What can be done to avoid leading edge erosion?

There are several products available on the market designed to address the issue of leading edge erosion in wind turbine blades. These products can generally be classified into three categories: LEP shells, paint solutions, and tape.

LEP shells, or leading edge protection shells, are designed to provide a hard and durable outer shell that can withstand the impact of airborne particles. Paint solutions, on the other hand, involve coating the leading edge of the blade with a specialized paint that can protect against erosion. Tape solutions typically involve applying a thin layer of specialized tape to the leading edge of the blade to provide additional protection.

Each of these solutions has its own set of advantages and disadvantages. LEP shells can provide excellent protection against erosion, but they can be heavy and difficult to install. Paint solutions are lightweight and easy to apply, but they may require more frequent reapplication over time. Tape solutions are relatively inexpensive and easy to install, but they may not provide the same level of protection as other solutions.

Ultimately, the choice of which solution to use will depend on a variety of factors, including the location of the wind farm, the severity of the erosion problem, and the operator’s budget and maintenance priorities. By carefully evaluating the different options available and selecting the most appropriate solution for their specific needs, wind farm operators can help to extend the life of their turbine blades and maximize their energy production.

How are the leading edge protection products tested?

Ensuring that leading edge protection products can withstand the harsh operating conditions of wind turbines is crucial to their effectiveness. To test the different products available, a rain erosion tester is used.

The rain erosion tester is designed based on the principle of a 3-bladed helicopter. Each test specimen is shaped like the leading edge of a wind turbine blade and is then accelerated while small droplets of water are released above it. The droplets fall and hit the fast-moving test specimens, simulating the conditions that blades experience in the field.

The test is run for a specific period of time, and after each period, images are taken of the test specimen to evaluate its performance and determine if any damages are present. This information can help manufacturers and operators to better understand how the products behave and perform under various conditions.

By subjecting leading edge protection products to rigorous testing, wind farm operators can select the best products for their specific needs, ensuring that they are able to effectively protect their turbine blades from leading edge erosion and extend the lifespan of their equipment.

Leading edge erosion is one of the easier defects to tackle?

Despite being a common defect type in wind turbine blades, leading edge erosion is one that is relatively easier to manage and control. Frequent inspections can help operators keep tabs on the rate of erosion and take steps to mitigate risks.

Many newer blades are now equipped with factory-installed LEP, which can significantly extend the lifespan of the leading edge. However, wind farms located in erosion-prone areas may still face higher costs over time to protect their equipment with leading edge protection.

Repairing leading edge erosion before it becomes structural is key to reducing repair times and costs. In fact, repairing erosion in its early stages can cut repair times by at least half.

By monitoring and addressing leading edge erosion, wind farm operators can maximize the lifespan of their equipment, optimize energy production, and reduce the overall costs of maintenance and repair.

Dirt And Contamination

Dirt and other contaminants on wind turbine blades can cause a reduction in the efficiency of the blades, leading to lower annual energy production. Just like with leading edge erosion, it is important to regularly inspect and maintain the blades to ensure that they are clean and operating at optimal levels. In fact, many wind farms now use automated cleaning systems to remove dirt and debris from the blades, helping to maximize energy production and reduce maintenance costs.