The surface of the wind turbine blades is designed to withstand the relentless forces of nature, exposed to a barrage of elements: wind, rain, hail etc. In this blog post we will dig more into some of the wind turbine blade surface defects that are observed in the industry. Some progress has been made in describing the different defect types. In this article we present our categorization, how these surface related defects are defined, and the distinguishing characteristics of each type.

Voids

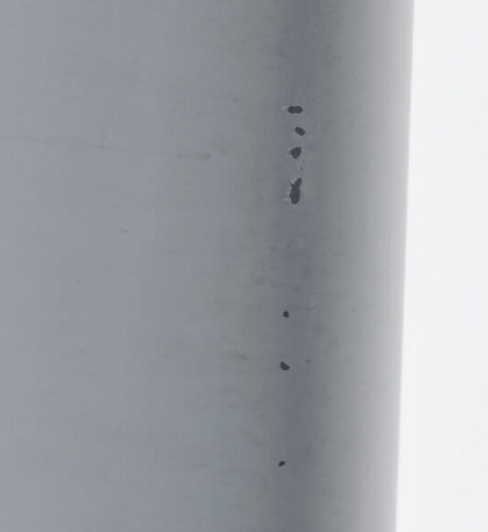

Void is a generic name for pinholes, air inclusions and air pockets in the surface coat. The cause of occurrence for pinholes and other void types are different. However, all voids are related to flaws during the coating process at the factory or during onsite repairs.

Voids in paint are caused by imperfections and contamination in the surface during final coating. Voids in filler and surface mat are caused by air inclusions in the filler or top layer Epoxy.

Voids weaken the surrounding surface coat, enabling other surface defects or erosion to develop. Voids do not have an impact on the blade integrity, but in erosion zones the presence of voids accelerate the development of erosion.

Defect indicators:

- Voids in paint appear as pinholes in the surface, ranging from 1-4mm^2

- Voids in the filler and surface mat appear as sharp-edged slots in the blade surface, ranging from 5-1000mm^2

- Appear as single defect or in clusters

Interchangeable defects:

- Chipping, rough edges around defect.

- Peeling, larger area of missing coating in the same layer.

- Erosion, continuous strip of missing surface coat in different layers on the outer 1/3 of LE.

- WLA, Burn-mark or contamination around defect.

Chipping

Chipping is a secondary defect; it only occurs after another surface defect has created a breach in the surface coat that chipping can develop from.

Chipping is the consequence of sand, rain, hail and other particles impacting on an exposed surface coating. On a healthy surface coat, these impacts would have neglectable effect on the coating as they would rebound. But due to an opening caused by other defects the particles can impact directly on the coating layers.

Chipping mainly affects brittle materials and is therefore limited in development to the surface laminate.

Due to its limitation, chipping does not have an impact on the blade integrity.

In the LE erosion zone chipping can lead to accelerated erosion.

Defect indicators:

- Rough and uneven edges around the defect border.

Varying depths of the defects showing different surface layers

Interchangeable defects:

- Voids, sharp defined edges around defect

- Peeling, larger area of missing coating in the same layer

Erosion, continuous strip of

Peeling

Peeling is caused by poor adhesion between layers in the surface coat. The adhesion loss is due to either contaminated surface, insufficient grinding of substrate, fault in coating mix or material batch.

In severe cases peeling can leave several m^2 exposed to erosion and other weather effects.

The defect itself has little impact on the integrity. But the exposure of underlying substrate can lead to accelerated development of other defects.

Defect indicators:

- Rough and uneven edges around the defect border.

- Varying depths of the defects showing different surface layers

Interchangeable defects:

- Voids, sharp defined edges around defect

- Peeling, larger area of missing coating in the same layer

- Erosion, continuous strip of missing surface coat in different layers

Want to learn more?

In this blog, we have delved deeper into the various types of defects and damages found on wind turbine blade surfaces. We have explored their definitions, the processes through which they develop, and their interchangeable characteristics.

If you’re eager to broaden your knowledge on wind turbine blade surface defects and damages, we offer specialized blade training programs designed to enhance your expertise in blade-related technologies. Our training covers topics like blade-related defects, lightning protection systems (LPS), and the fundamental principles of blade construction, providing you with a comprehensive understanding of these crucial aspects..

Click here to learn more