Wind Turbine Blade End of Warranty Best Practices

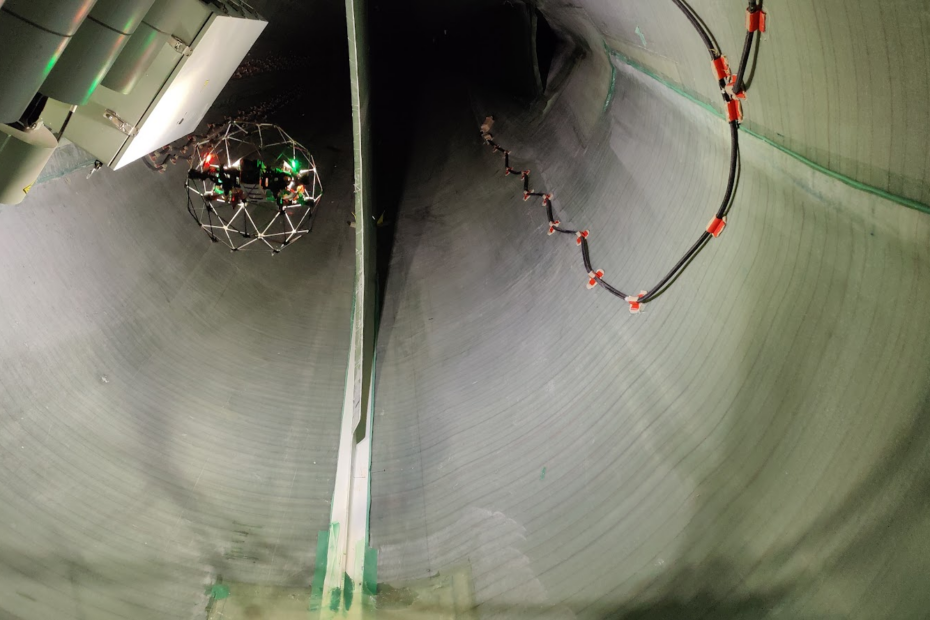

Introduction End of Warranty (EoW) campaigns mark a crucial phase in the operational life cycle of wind turbines. These campaigns involve thorough inspections of major… Read More »Wind Turbine Blade End of Warranty Best Practices